Agglomeration Technology

Main features are as follows:

- 30% salt metals at most in the binder

- Technology to coat the particles with only 1% of the binder

- Withstands temperatures up to 1600 C before loosing its properties

Applications for the technology

- Can recover fines from the chloride process. As particles become to small as they are digested to TiCl4 they blow out to the bag house. This represents approximately 6 to 15% of the feed to the chloride process.

- Can recover rutile fines in sands with the right chemistry for the chloride process.

Upgraded TiO2 Feed Stock

The wholly owned Long Point resource was used to make an upgraded TiO2 feed stock. Main features are 35% TiO2 in the feed stock with 0.4% V2O5 and scandium. Products from the ore are as follows:

- 0ver 80% TiO2 feed with low MgO

- High purity V2O5

- Sc2O3

Fancamp has many resources of iron titanium with vanadium and now investigating these for their potential for scandium as well.

Titanium Metal

Fancamp has been progressing well with the development of the titanium metal in a novel way that is greener and lower cost. Main features:

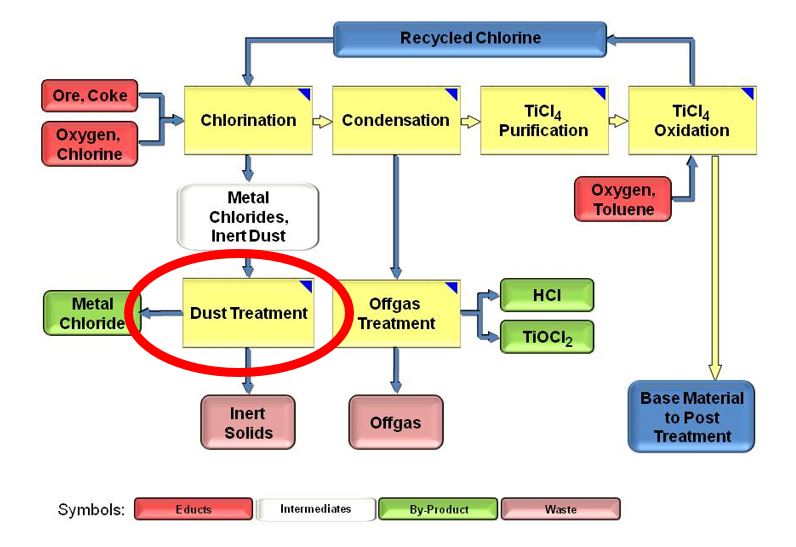

- Closed loop and recycle the ingredients back to the front end

- By product of fertilizer

- Titanium metal and its alloys

- Titanium metal for 3 D printing uses.